Sintered filter elemint kears filter hege effisjinsje

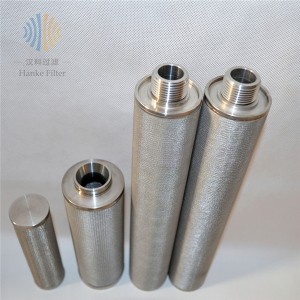

Sintered filter elemint is makke fan sintered gaas of ss poeder as grûnstof. Sintered gaas is in nij soarte fan filter materiaal dat is makke fan in fiif-laach roestvrij stiel tried woven gaas troch it proses fan "sintering", filter rating is 1 -200 mikron.

It wichtichste punt fan sintered filt filter is dat in grut oantal hege-precision welding wurdt used.To garandearjen roundness en plat, sintered wire gaas filter cartridge wurdt sintered nei it brûken fan rolling naad welding proses en metoade fan korreksje weld, it kin meitsje de algemiene look moaier.

Foardiel:

Uniform gat, krekte filtraasjerate

Hege hurdens en goede abrasion ferset

Excellent ferset tsjin eroazje, waarmte en druk

Oanfraach:

Polyester

Seewetter behanneling

suvering filter stof

Petrochemical, Propaan Dehydrogenation

Polysilikon, sinnebatterij

Ierdgas

Vulkanisaasje

Pharmaceutical, petroleum raffinaazjetechnyk

Drinken, iten ferfine of fytse

Kwaliteitsbeweitsing:

Preeminint ûndersyk en ûntwikkeling

20 jier ûnderfining

Avansearre ûntwerpideeën

Standertisearre produksjeproses

Folsleine produksje apparatuer

Effektyf kwaliteitsbehear

Spesifikaasje

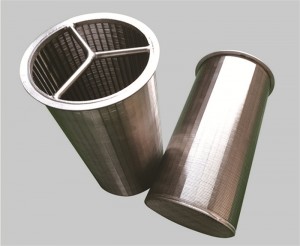

Sintered gaas (foegje ien laach 12mesh woven gaas ta, wurde dan 6 lagen sintered mesh, de drukresistinsje sil perfekter wêze)

|

Nominale filterwurdearring (μm) |

Beskermjende Layer Mesh |

Filtraasjelaach Mesh |

Fersprieding |

Fersterkende Layer Mesh |

Fersterkende Layer Mesh |

Dikte |

Luchtpermeabiliteit |

Bubble druk |

Gewicht |

Porosity |

|

1 |

200 |

400 x 3000 |

200 |

12x64 |

64x12 |

1.7 |

1.81 |

360 - 360 |

5 lagen |

Ca |

|

2 |

100 |

325 x 2300 |

100 |

12x64 |

64x12 |

1.7 |

2.35 |

300-590 |

||

|

5 |

100 |

200 x 1400 |

100 |

12x64 |

64x12 |

1.7 |

2.42 |

260-550 |

||

|

10 |

100 |

165 x 1400 |

100 |

12x64 |

64x12 |

1.7 |

3.00 |

220-500 |

||

|

15 |

100 |

165 x 1200 |

100 |

12x64 |

64x12 |

1.7 |

3.41 |

200-480 |

||

|

20 |

100 |

165 x 800 |

100 |

12x64 |

64x12 |

1.7 |

4,50 |

170-450 |

||

|

25 |

100 |

165 x 600 |

100 |

12x64 |

64x12 |

1.7 |

6.12 |

150-410 |

||

|

30 |

100 |

400 |

100 |

12x64 |

64x12 |

1.7 |

6.86 |

120-390 |

||

|

40 |

100 |

325 |

100 |

12x64 |

64x12 |

1.7 |

7.10 |

100-350 |

||

|

50 |

100 |

250 |

100 |

12x64 |

64x12 |

1.7 |

8.41 |

90-300 |

||

|

75 |

100 |

200 |

100 |

12x64 |

64x12 |

1.7 |

8,70 |

80-250 |

||

|

100 |

100 |

150 |

100 |

12x64 |

64x12 |

1.7 |

9.10 |

70-190 |

||

|

150 |

50+100+50+30+30+100+50 |

2.0 |

25.00 |

50-150 |

||||||

|

200 |

40+80+40+20+40+80+40 |

2.0 |

26.00 |

50-150 |

||||||

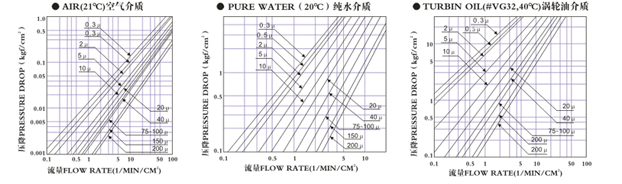

Differinsjaal druk flow kromme

|

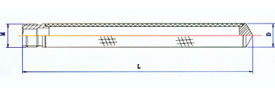

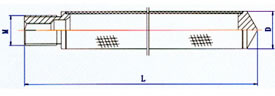

Model |

L |

D |

M |

Filtergebiet (M2) |

R |

Filter Media |

|

CF-14/65-R |

65 |

14 |

M10*1P |

0.002 |

2, 5, 10, 15, 20, 30, 40, 75 |

Stainless Steel Sintered Wire Cloth |

|

CF-14/250-R |

250 |

0.01 |

||||

|

CF-14/500-R |

500 |

0.022 |

||||

|

CF-14/1000-R |

1000 |

0.044 |

|

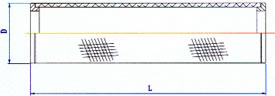

Model |

L |

D |

M |

Filtergebiet (M2) |

R |

Filter Media |

|

CF-25/250-R |

250 |

25 |

M20*1.5P |

0.019 |

2, 5, 10, 15, 20, 30, 40, 75 |

Stainless Steel Sintered Wire Cloth |

|

CF-25/500-R |

500 |

0.039 |

||||

|

CF-25/1000-R |

1000 |

0.078 |

||||

|

CF-30/500-R |

500 |

30 |

M20*2P |

0.046 |

||

|

CF-30/1000-R |

1000 |

0.093 |

||||

|

CF-30/1500-R |

1500 |

0.140 |

|

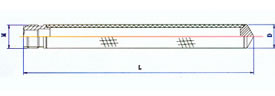

Model |

L |

D |

M |

Filtergebiet (M2) |

R |

Filter Media |

|

CF-50/250-R |

250 |

50 |

Dichtring of flange |

0.038 |

2, 5, 10, 15, 20, 30, 40, 75 |

Stainless Steel Sintered Wire Cloth |

|

CF-50/500-R |

500 |

0.078 |

||||

|

CF-50/1000-R |

1000 |

0.150 |

||||

|

CF-60/500-R |

500 |

60 |

0.094 |

|||

|

CF-70/500-R |

500 |

70 |

0.108 |

|||

|

CF-75/500-R |

500 |

75 |

0.115 |

|||

|

CF-90/500-R |

500 |

90 |

0.140 |

|||

|

CF-150/500-R |

500 |

150 |

0.230 |

|||

|

Opmerking: Binnenstipe fan filtereleminten kin in roestfrij stiel perforearre buis as maitiid wêze |

||||||

|

Model |

L |

D |

M |

Filtergebiet (M2) |

R |

Filter Media |

|

CF-16/390-R |

390 |

16 |

M16*1.5P |

0.02 |

2, 5, 10, 15, 20, 30, 40, 75 |

Stainless Steel Sintered Fiber Web; |

|

CF-50/500-R |

500 |

50 |

0.07 |

|||

|

CF-63/750-R |

750 |

63 |

0.15 |

|||

|

CF-65/266-R |

266 |

65 |

0.05 |

|||

|

CF-70/500-R |

500 |

70 |

0.10 |

|||

|

CF-70/1000-R |

1000 |

70 |

0.21 |